As implants placed immediately after extraction gain popularity in dentistry, finding out what implant types will quickly support loads is increasingly important. Now Italian researchers have compared the clutch techniques of two different dental implants to better understand how they perform under load in the mouth (Journal of the Mechanical Behavior of Biomedical Materials, June 2014, Vol. 34, pp. 1-7).

These results could help clinicians make better-informed decisions about what materials are best-suited to the specific needs of each patient, according to the researchers from the department of industrial engineering at the University of Italy and Leone Orthodontics and Implantology, both in Florence.

"It was assessed that the housing preparation technique has a great influence on primary stability," they wrote.

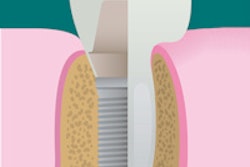

The researchers compared the primary stability of implants with a cylindrical (CL) and truncated cone (TC) shape. CL implants, with a straight wall interior from the threads, have been widely used in "classical cases," while TC implants are tapered in shape, giving them a self-threading ability with threads that protrude more, resulting in a better grip on the housing, they explained.

While investigating, the researchers noted advantages to either type. "As TC supports loads more than CL, it would always be convenient to use a TC implant, especially for relatively weaker bones," they wrote. "On the other hand, the use of a CL implant presents clear advantages considering the simplicity of the surgical phase."

Those factors should be present in the minds of clinicians when selecting the type of implant they will use, because they give "qualitative indications for choosing the appropriate installation," the researchers added, "taking into account both the values of the maximum torque -- directly related to the stresses on the bone due to the screwing phase -- and the critical load."

Testing the implants

Both implants were modified so that a pin may be inserted, which connected them to a pullout testing machine. The researchers selected a housing material with properties similar to that of a jaw bone: polyurethane grade 20 (PU20) and grade 40 (PU40) to simulate low- and high-density spongy bone, respectively.

"The structural contribution of cortical bone was not considered due to the negligible thickness," they wrote. The researchers also used a third material, polyvinyl chloride (PVC) plastic, for increased variance in the method of housing preparation.

Holes in the polymeric housings were prepared with a surgical kit in a way that mimicked implant surgery. First, they produced a 2.8-mm pilot hole with a depth of 10 mm and gradually increased the diameter to 3.5 mm or 3.8 mm. Altogether, they tested 120 samples, with 10 tested under 12 different conditions.

To conduct the pullout test phase, the researchers used an Instron machine with a custom-made gripping system. The applied force and displacement force were measured with a transducer; the displacement of the crosshead of the machine was measured and recorded; and the torque applied to the implant while screwing it into the housing was measured with a digital torsiometer.

The researchers found that the TC implant without tapered housing was the most stable. Meanwhile, contrary to their expectations, they observed no substantial differences between the two types of implants with tapered housings. Nor was there a significant difference in stability between implants placed at 3.5 mm or 3.8 mm. However, "when both TC and CL implants were built with the same preparation method, the geometry of TC implants led always to a higher primary stability," they noted. "TC implant reached higher loads with less deformation of the system."

While analyzing the PVC housing results, the researchers concluded that "the best technique for installing a TC implant is to realize the hole with two end mills of different diameters without any tapping," they wrote. "The absence of tapping allows the implant to adapt on the housing in function of its geometry."

The researchers stressed the importance of the preparation technique. "In this study, it was assessed that the housing preparation technique has a great influence on primary stability," they concluded.