Finnish researchers have developed a new surface treatment process for orthopedic and dental implants that may reduce the risk of infection.

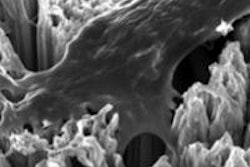

Implants are commonly made from titanium alloys, which are made porous to prepare them for medical use. While this ensures good contact between the implant and bone, it also allows bacteria to adhere and grow both on the surface as well as inside, leading to an increased risk of infection. An estimated 10% to 15% of postimplant complications are caused by bacterial infections.

A thin coating of a biomaterial called hydroxyapatite (HAP) or bioactive glass (BAG) is typically applied to orthopedic and other implants to alter the surface properties. These coatings improve the body's ability to recognize a foreign object in a more amicable way and promote implant integration into surrounding tissues. Excessive stresses can cause premature cracking and removal of the coating layer during the heat treatment process, which can lead to an increased risk of infection, according to the researchers from Aalto University.

By adding a certain amount of another compound called beta-tricalcium phosphate (β-TCP), such stresses are reduced, preserving the biomaterial coating better, they explained.

Minimizing the risk of coating destruction and bacterial adhesion, and improving cell proliferation, allows the implant surface to achieve its function in an optimal way, according to the researchers.