Researchers at the University of California, Irvine have developed a system designed to transform human urine into hydroxyapatite (HAp), a material used in dental implants, according to a university press release dated June 17.

Furthermore, this biological system uses synthetic yeast cells to convert urine from wastewater into HAp, a naturally occurring mineral that gives tooth enamel its hardness, according to the press release.

“This process achieves two goals at the same time,” David Kisailus, PhD, co-author and professor of materials science and engineering at the university, said in the release. “On the one hand, it helps remove human urine from wastewater streams, mitigating environmental pollution and the buildup of unwanted nutrients; and on the other hand, it produces a material that can be commercially marketed for use in a variety of settings.”

In mammals, osteoblasts are specialized cells that extract calcium phosphate from bodily fluids and secrete it as HAp. However, these cells aren’t suitable for large-scale industrial production, so the research team turned to a synthetic alternative.

They developed osteoyeasts, engineered yeast cells that break down urea and raise the pH of their surroundings, prompting calcium and phosphate to accumulate in tiny cavities within the yeast. These minerals are then secreted and crystallized into HAp, according to the release.

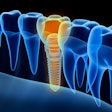

The team’s biologically inspired system converts human urine from wastewater into this valuable compound. HAp is lightweight yet strong and durable, making it ideal for dental implants and more. If produced economically at scale, urine-derived HAp could also offer a renewable, biodegradable alternative to plastics and other construction materials.

Additionally, the researchers conducted an economic analysis showing the method’s potential to both reduce environmental damage from wastewater and tap into a market projected to exceed $3.5 billion by 2030. The project received funding from the U.S. Department of Energy, the Defense Advanced Research Projects Agency, and the Air Force Office of Scientific Research, according to the release.

“We are currently developing strategies to leverage his yeast platform with our 3D printing and structural knowledge to make multifunctional architected materials,” Kisailus said.